I was asked by Roberta how I make the "buttons" that I put into the back cushions on my furniture. I thought that was a good topic for a tutorial for this month.

This is not an upholstery tutorial. I have that listed on the left side of the blog, Make and upholster a 1 inch scale chair.

I have a back cushion cut out and I have the button placement marked on the pattern.

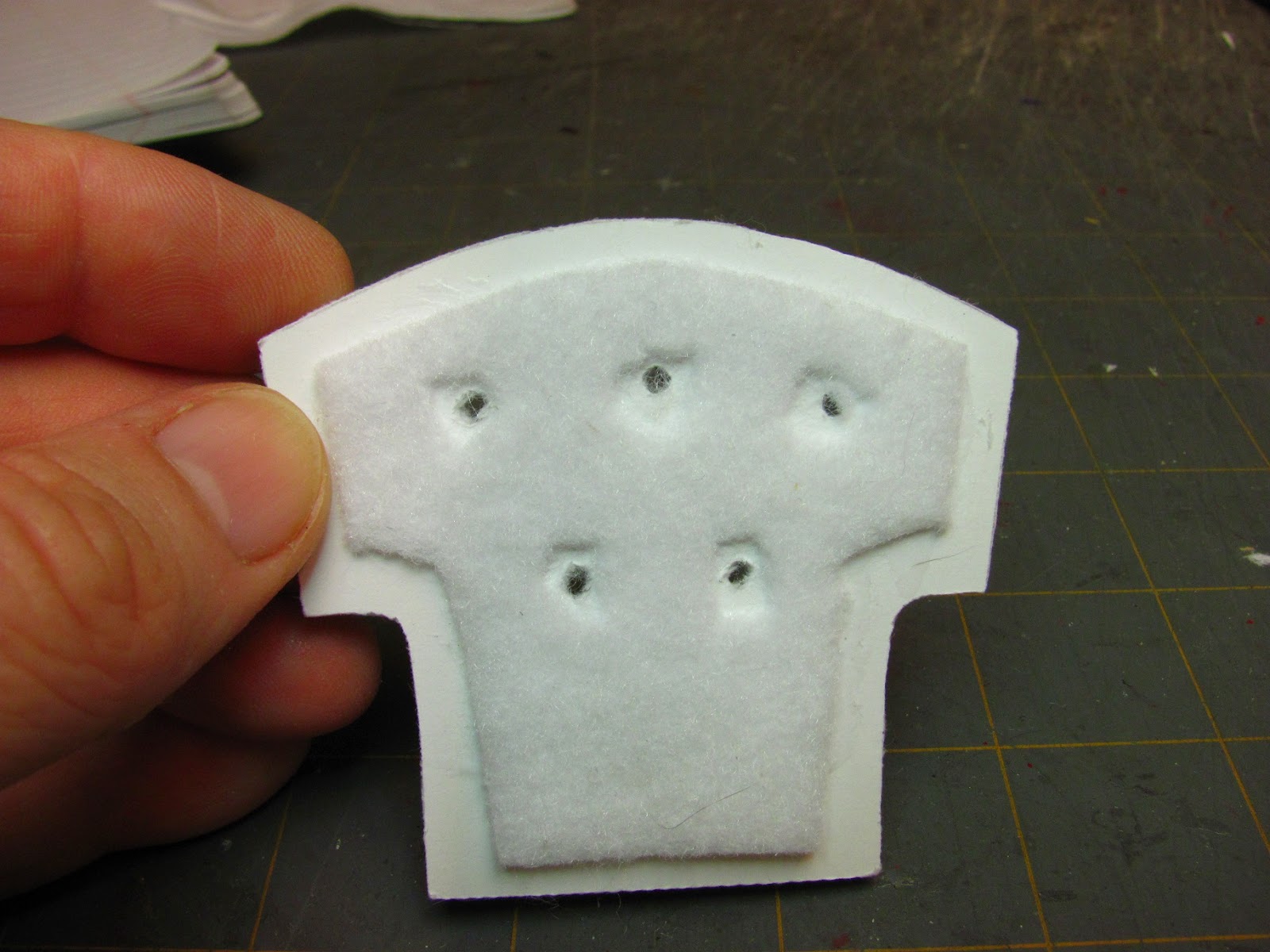

Place your pattern on the cushion back and punch through the foam core with a pencil to mark placement.

There are the holes made by the pencil.

I am using my Dremel to drill holes through the foam core. That's probably a 1/16" bit.

Use tacky glue and apply it on the back cushion. Can you see that I have left the area around the holes without glue?

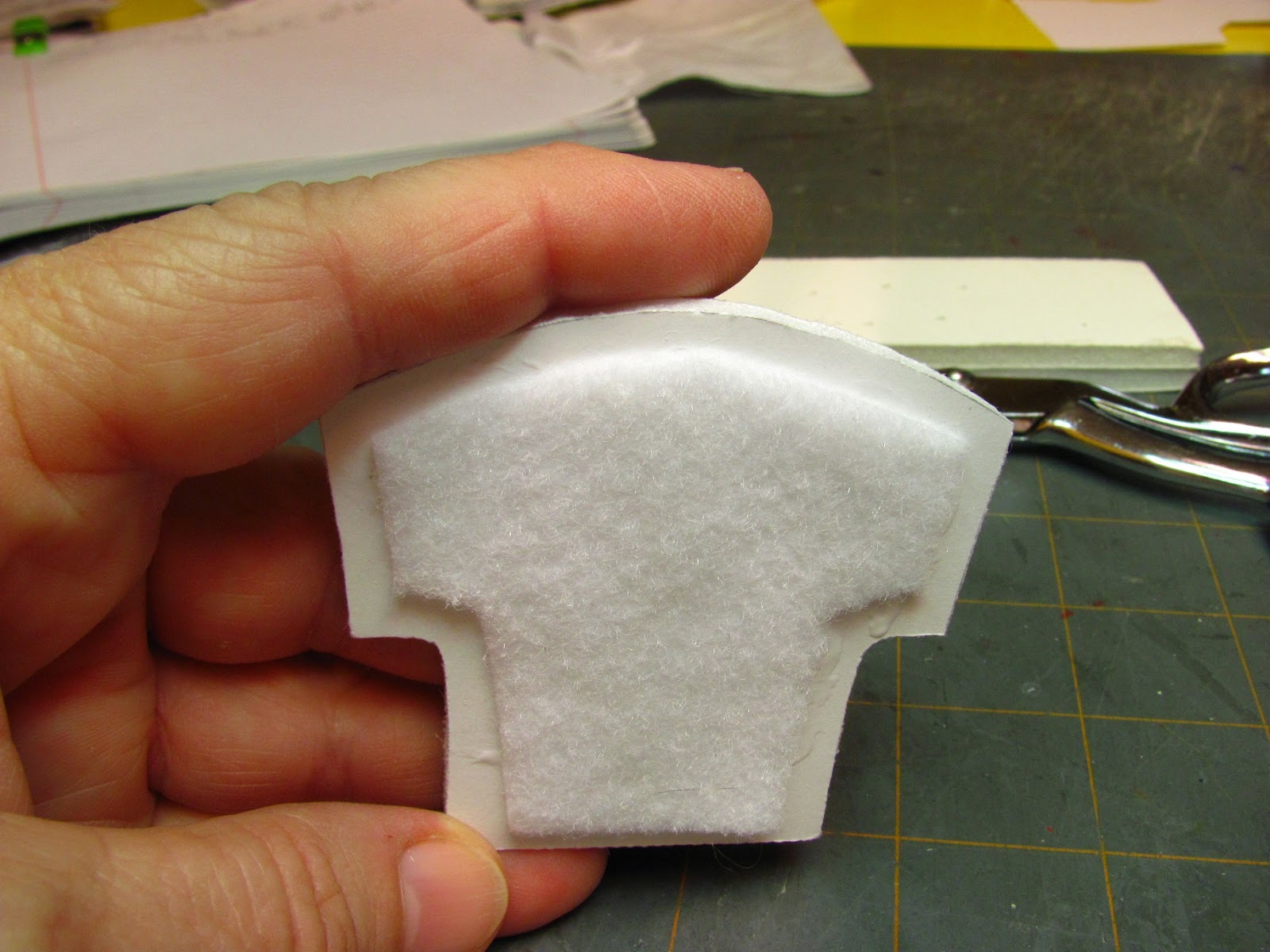

This is my first layer of Thermolam Plus. I buy this at JoAnn's or Walmart, do not buy the fusible.

With your sewing scissors cut out around the holes.

I say sewing scissors because we don't use those to cut paper with, do we? We only use our sewing scissors for fabric so they stay sharp.

This is the second piece of Thermolam Plus.

The second piece is glued on and the holes are cut out.

This the last piece of Thermolam Plus.

I have this piece glued on, I will not cut the holes out on the last piece.

I've cut a large enough piece of fabric out for my back cushion.

Turn the fabric to the wrong side and place your pattern on the fabric and mark the holes.

My holes have been marked.

I have a tip for you, on a flat back cushion like this you can enlarge your pattern on the computer by a very small amount, maybe 5%. This spreads the holes out and gives more fabric to be tucked into the dimples you are going to be making for the buttons to set into. If you use more padding on the back cushion you would want more fabric to go into the dimples. It's a little trial and error on just how much to enlarge.

On a curved back cushion, like in the first picture at the top you do not have to do this. Mark the pattern on the fabric as is, the curve takes care of giving you extra fabric.

I use button hole or carpet thread to pull the dimples with. You could probably use sewing thread just as well.

I double my thread and make a knot at the end.

Start the needle from the back of the back cushion. Use the marks on the fabric to line up your needle.

Yes, the knot will go through the hole, it will catch on the Thermolam Plus.

Take a small stitch on the front and come back out at the back.

Go to the next hole in the back, insert on the mark on the fabric, take a small stitch and come back out and on to the next hole.

Don't pull too hard, the dimple doesn't have to be deep.

I've sewn all of the dimples and I've gone back into the first hole and took another stitch.

Knot off and cut your thread.

Here is the front of the cushion with all of the dimples sewn in.

If I were making a chair I would be ready to glue the cushion into it now.

To make the buttons I use a leather punch. I bought this at a hardware store, I know that Michaels also carries these.

I use white glue, too. I want the card stock to stay wet for awhile and the white glue does not dry too fast.

I also use a double ball stylus. I bought this one at Michaels.

I use craft foam to shape the buttons. This is also available from Michaels.

Apply white glue to a piece of card stock and press your fabric onto it.

I am using a contrasting fabric so you can see the buttons when I'm finished.

The leather punch is not designed to cut through fabric, it's not sharp enough and it's cutter presses against a flat metal surface. The fabric isn't thick like a piece of leather. A paper punch doesn't work. The card stock and fabric are wet and hard to cut out.

So what do you do . . . .

I place another piece of card stock on top of the fabric. This gives a tiny bit of depth for the cutter to cut through and it works. I have put the extra card stock under the card stock that is glued to the fabric but that is hard to separate after the circle is punched out. If you don't separate the two pieces of card stock you run the risk of the button falling off because you didn't glue the button on, you glued the extra card stock on.

This does work, it just takes some practice.

Here are my circles setting on two pieces of craft foam.

I am using the small end of the double ball stylus to shape the circles into buttons.

The size of circle you cut is up to you. For this tutorial I used the 1/8" cutter.

My buttons are shaped. Leave them in the craft foam to dry. It's important to let them dry. You will be pressing them into glue and if they are not hard and dry they will loose their shape and you will have to start over.

There is one button.

Apply a dab of tacky glue into the dimple.

I have all of my buttons glued into the dimples of the back cushion.

O.K. so they aren't real buttons but I think they look great on a piece of miniature furniture.

I hope you are all getting outside, I really think winter might be over!!

If you have any questions please e-mail me at camceiling@frontiernet.net.

If you have pictures for the Follower's Gallery send them to camceiling@frontiernet.net.

Have fun, Expand on it, Make it better . . . . .

Just Keep Making Minis!!

Kris

P.S. I'm sorry I forgot to put the reminder about sending in your photos of finished tutorials, please send me photos, the address is camceiling@frontiernet.net.

If you have any questions please e-mail me at the same address and I will do my best to answer them.