I can always count on the followers to help me out, thank you, Terry. It's a padded seat, I needed that to describe a chair I have over on CDHM.

Merry Christmas and Happy New Year!

Kris

Pages

▼

Friday, December 24, 2010

Thursday, December 23, 2010

Upholstery Term?????

I have a question for you, I always turn to you followers for answers. What is the name or term for the type of seat on an upholstered chair that is not the removable seat cushion type, it would probably have springs in the seat and just be upholstered into the chair? If anyone can help I would really appreciate it, Kris

Suede Paper 2

I used coconut. I found a good website for rugs, www.woodworkersauction.com. I know it doesn't sound like a rug site, but get on and go to rugs. I "save image" into my minis file, then when I need to print I will double click on the picture and then it goes into the program where you print photographs. I will click "fix" and set the saturation all the way up, then click print and choose my size. I have been successful in sending the paper back through the printer to print the rug over at least 3 times. I have also been unsuccessful doing this, it will double expose if not exactly lined up. It's always a "keep you fingers crossed kind of thing". When it works, it is so good, the colors and patterns are beautiful. When it doesn't, you are wasting paper. So mostly I just print once and say I'm satisfied! It's fun to do and you are making them yourself, of course you can drive yourself crazy looking for the "perfect" rug. Have fun! Kris

P.S. I just went to the website and it is "under construction", I don't know what they are doing, I hope they will still have rugs. What is so perfect about this particular website is the rugs save in a large size, we don't have to enlarge them. Will keep an eye on the site and hope for the best.

P.S. I just went to the website and it is "under construction", I don't know what they are doing, I hope they will still have rugs. What is so perfect about this particular website is the rugs save in a large size, we don't have to enlarge them. Will keep an eye on the site and hope for the best.

Wednesday, December 22, 2010

Suede Paper

I have finally gotten the color cartridge for my printer so I tried out the suede paper I bought from www.franticstamper.com. I am glad to report that it does work in the ink jet printers. The suede paper I bought from www.dragonflyintl.com worked the first time, but I couldn't get it to work after that. That paper came in a shrink wrapped package, flattened, after I opened it I think it "fluffed" out and became too think to run through the printer. I left the franticstamper paper set out for a month and it went through the printer just fine. Soooooo, if you want to make some quick and inexpensive rugs buy the suede paper from franticstamper.

See 'ya next year! Kris

P.S. This stuff is for making the quick mini rugs I wrote about in an earlier blog. I told you to buy the suede paper from someone else, buy it from frantic stamper instead. Copy and paste rugs off the Internet to make your rugs.

See 'ya next year! Kris

P.S. This stuff is for making the quick mini rugs I wrote about in an earlier blog. I told you to buy the suede paper from someone else, buy it from frantic stamper instead. Copy and paste rugs off the Internet to make your rugs.

Wednesday, December 15, 2010

Turning on a Drill Press, Part 2

This is a picture of a round cutter, it dropped out of the line up and I did want to show it to you. I generally use cutters that measure 1/16" or less.

This is a picture of a round cutter, it dropped out of the line up and I did want to show it to you. I generally use cutters that measure 1/16" or less.We are ready to start chucking up some wood.

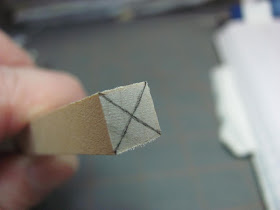

Mark the center on one end of the square stock of basswood.

Mark the center on one end of the square stock of basswood.Make a hole in the center with a "T" pin.

Place the stock into the chuck and the end of the stock on the pin. Tighten the chuck. We don't want the bottom of the stock to be against the wood holding the "T" pin, leave a little space at the bottom. If your stock is touching the wood holding the "T" pin and you begin turning you are going to smell burning wood because of the friction between the two pieces of wood.

First you round with sand paper to the diameter you need for your project. I cut a pattern from poster board; the first one is for diameter. You can buy calipers for measuring; this poster board works fine, though.

Sand until you have the diameter needed.

Ahh, design - For right now that's trial and error. Basically playing with the cutters, they aren't lathe tools. You will have to try them out and get the feel of what you can do with them. For my designs I go from pictures and try to copy what I see.

I'll measure where I need to make the first cuts. I am using Joy's lamp for an example. Most of the time I convert a full size turning to 1 inch scale measurements. For this example the picture of Joy's lamp was the right size to measure from. The cuts are where I am going to be starting and stopping the shapes on the turning.

I use this piece of poster board with the tick marks to transfer the measurements to the stock on the drill press.

Right now you can just play with making the shapes where you want to get the feel of the turning drill press and the cutters.

I turn on the drill press and using a pointed cutter I cut into the wood at the marks I've made.

I use any combination of cutters and sand paper to get the shapes I want. The cutters aren't designed for this, so it's trial and error. What works for me may not work for you, or you are not comfortable with that particular cutter.

When you are satisfied with the piece, finish off with fine grit sand paper.

This is a large turning, it's for a floor lamp. The smaller the turnings, the more difficult the turning is to do. Basically, the drill press is a makeshift lathe, it's not going to do everything a lathe can. For making spindles for things like this floor lamp base, table lamp bases or spindles for a porch railing the drill press can work for you.

Doing all of this on the Dremel is pretty much the same but your turnings are going to be smaller in diameter, not over 1/4" in diameter, (using the 1/8" dowel glued into the top).

I hope some of you are able to try this out.

Have fun, expand on it, make it better, just keep making minis!

Merry Christmas and Happy New Year ! ! ! !

December Project, Turning on a Drill Press, Part 1

This blog is about turning on a drill press or Dremel with it's Workstation. The name drill press implies drilling holes; yes, that's what it is for. Turning is making spindles, like on a stair railing. You can make lots of symmetrical turnings for other things, too. Normally a lathe is used for turning; it holds the wood horizontally, the drill press holds the wood vertically.

This blog is about turning on a drill press or Dremel with it's Workstation. The name drill press implies drilling holes; yes, that's what it is for. Turning is making spindles, like on a stair railing. You can make lots of symmetrical turnings for other things, too. Normally a lathe is used for turning; it holds the wood horizontally, the drill press holds the wood vertically.If you have never used a drill press please have the person you are borrowing it from read my blog. Have them help you get started. I should also mention to wear eye protection when using the drill press and Dremel/Workstation.

We also have a lathe and my husband makes beautiful things on it. Right now his is making oak spindles for a staircase. I've tried turning on the lathe and I don't like it. I seem to be able to turn more easily on the drill press. With a lathe you can do more like making bowls and vessels. I am busy upholstering furniture and haven't gotten to that point.

I have a Dremel and its Workstation. The Workstation holds the Dremel in a drill press set up. I started using the combination to turn porch spindles to save some money on a project. The results aren't always symmetrical. The Workstation isn't as stable as a drill press so one side of the turning might have a little less design cut into it. We can always turn that side to the wall!

I have a Dremel and its Workstation. The Workstation holds the Dremel in a drill press set up. I started using the combination to turn porch spindles to save some money on a project. The results aren't always symmetrical. The Workstation isn't as stable as a drill press so one side of the turning might have a little less design cut into it. We can always turn that side to the wall!If you already have a Dremel maybe a Workstation would be a good accessory for you. I like it for drilling multiple holes, say in seats for wicker. The Workstation only works with certain models of Dremel so check before making your purchase.

If you find you like turning, a bench top drill press runs around $100.00 at Home Depot or Loew's. It's a cheaper buy than buying the Dremel and Workstation together. Lathes generally cost more than drill presses.

Another difference between the drill press and Dremel/Workstation is that the Dremel will only accept up to 1/8" diameter bit, cutters and for turning, wood. To turn a larger piece of wood you have to drill into the center on one end and glue in a 1/8" dowel. The dowel will then be placed into the chuck.

Another difference between the drill press and Dremel/Workstation is that the Dremel will only accept up to 1/8" diameter bit, cutters and for turning, wood. To turn a larger piece of wood you have to drill into the center on one end and glue in a 1/8" dowel. The dowel will then be placed into the chuck.

You see in the picture I have clamps holding a piece of wood with the sharp end of a "T" pin in it. You will have to do this with the Dremel or drill press.

The "T" pin holds the bottom of the wood, while the chuck holds the top.

The chuck on this floor model drill press holds 3/8" square stock. If I want to turn something from larger stock I would drill a hold in the center on one end and glue in a 1/4" dowel, (I mentioned this above for the Dremel). I am working in miniature and I don't do this very often.

A lathe has chucks for turning larger diameter wood and a "center" at the end to hold the wood, it's for turning wood. We are making the drill press do something it's not intended for. But a drill press is something a lot of fathers and husbands have in the workshop/garage.

Use "hardwood" for the "T" pin set up, not a pine 2x4. The "T" pin gets hot and it will drill itself down and out of the weed after you turn a few pieces and you will have to hammer it back up into the wood to stick out again. Google hardwood and you will find names of wood that qualify.

After you have made this "T" pin set up use clamps to secure it to the drill press table or the Workstation table. I've used my husband's wood clamps but "C" clamps work fine.

Clamping the "T" pin set up takes a little time because it has to be centered under the chuck. If it's not centered your finished turning won't be symmetrical.

I will chuck up a piece of wood and line up the pin under it. Make sure it's centered front to back and side to side.

I've got my spindle speed set at 2300. Most drill presses have a belt at the top, it's under a lid, to set different speeds. Most Dremels have speed settings, when you turn the Dremel on set the speed where you are comfortable. If you have trouble with the turnings breaking, change your speed.

So now you are set up. I use basswood square stock. You might think to use dowels, they are already round. Dowels are hardwood and will dull my steel cutters. Woodcarving sites have carbide cutters, just haven't found the need to buy them. Carbide cutters would last longer. I use Dremel's engraving cutters all sizes and shapes. I use sand paper; 120 grit for rounding the square stock. I use the finer grits to finish the turning. I use the round ball shape the most, smallest diameter on up. Dremel has 3 sizes of 4 different shapes. Micro-Mark carries cutters, too. I have found that the woodcarving sites are cheaper than Micro-Mark, though.

End of Part 1

Sunday, December 12, 2010

Merry Christmas to all !

I am putting up my Leg Lamp for you to see since it's the season for the movie, "The Christmas Story". I love that movie and watch it a lot at this time of year.

If you have seen the movie you know about the lamp. The father wins second place in a contest he enters and wins the lamp. He loves it, the wife doesn't and "accidentally" breaks it when she is watering flowers.

I love the lamp and made one in 1 inch scale. Giselle Sullivan made the leg for me, with a hole in the bottom for the wiring to go through. She was so helpful with getting the stocking on, Matte Modge Podge. The shade has a wooden frame I steam bent the pieces to the shape I wanted. The shade in the movie is large and I wanted the same shade so I couldn't use a ready made miniature. I mixed some dye I had to get the color of silk I wanted. The craziest part was the fringe, I twisted embroidery floss back onto itself a little at a time for each strand. Took forever, I am crazy, but I think it looks great. One day I will get around to making a Christmas scene with the lamp in the window just like the movie!!

TTYL Kris